Mezzanines, or mezzanine platforms, are a popular type of industrial furniture; they are essentially un-walled, raised platforms. Note that the mezzanine card is not a type of industrial mezzanine. Mezzanine cards are instead a particular type of printed circuit board (PCB) assembly. Read More…

As a manufacturer of mezzanines, including inplant modular offices, exterior steel buildings, guard buildings, fork liftable and crane liftable buildings, multi-level buildings and mezzanines, Abtech offers turnkey installations or packages for install by end user. Our modular structures are constructed of steel, are free-standing & manufactured under strict quality control methods.

Since 1982, Equipment Roundup Manufacturing has manufactured products such as mezzanines. Our mezzanine structures include mezzanine systems, mezzanine floors, industrial mezzanines & plant mezzanines.

Are you looking for a ready-to-use mezzanine? Our team can handle the design and install so that when we're done, it is ready for you to go to work. When you choose PWI we drastically increase your workspace, in many cases customers create new work or additional storage space. Our steel mezzanines are an affordable alternative to new construction and ensures you are getting the most out of your...

Since 1985, Donobrog has been providing low cost easy mezzanines, inplant offices, pick modules, pallet racking and shelving systems…. “Turn Key – New and Used””. Sales, Engineering, Fabrication and Installation. Our labor also can tear down, move, re-assemble and repair existing storage systems. Contact us to discuss your facility improvements.

ResinDek® flooring is the solution for mezzanines, work platforms, pick module flooring, and equipment storage. ResinDek® panels have been installed in distribution centers, manufacturing plants, cold storage facilities and many other applications because of its strength, durability, versatility, and variety.

Since 1995, Panel Built has been a leading manufacturer and distributor of modular buildings. Our booths and partitions are available in a wide range of materials including solid phenolic, metal powder-coated, and high-pressure laminate. Panel Built also has an extensive list of washroom accessories including, but not limited to waste receptacles, combo towel waste unites, and grab bars. If our...

More Mezzanine Manufacturers

Mezzanine Applications

Mezzanines are primarily utilized to expand space for workers and equipment, to house unused materials, and to boost overall workspace efficiency. Their practical design has earned them the nickname “work platforms.” Beyond storage, mezzanines also serve versatile functions. For instance, they can act as a surface or ceiling for office areas, allowing for the construction of office spaces both above and below the mezzanine level.

A mezzanine is an extra level built between the main floor and the ceiling, effectively creating an intermediate space that doesn’t count as a full floor in a building’s total. By utilizing the vertical space, mezzanines enhance the functionality of a structure, allowing for more usable area without adding an additional floor. This versatile feature can be integrated into various types of buildings, optimizing their spatial efficiency.

Some solutions facilitate smooth transportation between mezzanine levels and the ends of buildings, and can even shuttle guests and visitors. They also offer auditorium-style seating. Mezzanines are frequently utilized by service companies, distribution centers, and suppliers.

Mezzanines are designed to enhance the functionality of high-rise buildings, offering valuable space without occupying too much room. They often serve as office areas, providing a comfortable working environment while maximizing efficiency. In industrial settings, mezzanines function as catwalks, allowing movement and access without disrupting operations. In theaters, they form the front rows of the balcony, creating a distinctive viewing experience.

A mezzanine stands out from other structural setups primarily by covering 25% of the main floor’s area. This distinctive characteristic defines its nature, regardless of whether it resembles a balcony, a loft, or a more enclosed space.

A mezzanine, positioned between the ceiling and the main floor, doesn’t count towards the maximum floor area. It must cover at least one-third of the floor space beneath it. Mezzanines are typically built to enhance storage capacity or boost a property’s market value. Additionally, they usually require a minimum height of 2 meters both above and below the main floor.

History of Mezzanines

The term “mezzanine” carries two distinct meanings in French, both stemming from related origins. The French word “mezzanine” itself comes from the Latin “mezzanino,” a diminutive form of “mezzano,” which translates to “middle.” On the other hand, the French term “entresol”—sometimes adopted into English—can refer to either a mezzanine or a room that has been partitioned within a larger space.

Regardless of the term you consider, the dominant impression from the etymology of “mezzanine” is that these structures were originally perceived as elements that split vertical or horizontal spaces right in their midst.

Mezzanine platforms initially made their debut in theaters, where they served as the lowest balcony, enhancing seating arrangements. In French architecture, the concept of the mezzanine, or “entresol,” was also embraced, notably in the elegant apartments of Versailles.

During the Industrial Revolution, mezzanine applications expanded significantly. They found their utility not just in warehouses and storage facilities, but also gained popularity in department stores—an innovation that emerged as a direct result of industrialization. As mass production flourished, it paved the way for the rise of department stores, which in turn further amplified the demand for mezzanine structures.

Today, manufacturers offer a diverse selection of mezzanine products at accessible prices, expanding the possibilities far beyond what was once available. Since the 1990s, engineers have had access to a broader array of high-quality composite wood materials, enhancing their ability to design mezzanines that meet specific environmental, spatial, and strength requirements with greater precision. These structures have become indispensable in the industrial sector, and it’s certain that future innovations will continue to enhance their functionality and durability.

Types of Mezzanines

Mezzanines are incredibly versatile and can be found in a wide array of designs. Many free-standing mezzanines, for example, are prefabricated to allow for easy, modular assembly, often serving temporary needs with their adaptability. On the other hand, some mezzanines are more modest, essentially small platforms designed simply for storing tools or other items.

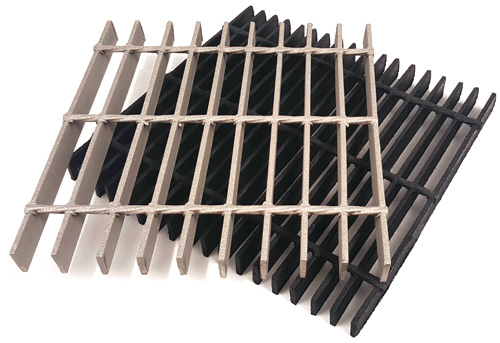

Steel mezzanine floors are widely used in both industrial and office settings. They come in two primary varieties: solid steel decking, which provides a seamless, sturdy surface, and open grid steel decking, which offers a more ventilated, lightweight option.

Closed steel decking features a checker plate or “Vastrap” design, which consists of simple steel sheets with a distinctive raised pattern on their upper surface. This pattern enhances grip, making the decking slip-resistant and safe for walking. When welded together, these steel sheets form a seamless, durable floor that meets the stringent cleanliness standards required by many industries.

Open grid mezzanines are available in two distinct styles: the open grid steel deck and the steel grating deck. The open grid steel deck features a bolt-together assembly with perforated steel plates bent into a C-channel shape, arranged in a staggered pattern. In contrast, the steel grating deck is a robust structure constructed from welded flat bars and round bars, forming a durable square grid platform.

Benefits:

Moisture Resistant:: Stainless steel remains resistant to rust even when it is regularly exposed to wet conditions.

Portability:: Steel’s lightweight nature makes it an ideal choice for companies needing temporary or mobile mezzanines rather than permanent fixtures. For instance, businesses operating in leased spaces often face the challenge of relocating their equipment at the end of their lease term. A portable steel mezzanine simplifies this transition, allowing for easier relocation or potential resale if it’s no longer needed.

Quick Installation:: Steel mezzanines are crafted off-site, typically pre-ordered to streamline the process. This approach significantly reduces the time and labor required for on-site construction.

Design Flexibility: Steel’s adaptability makes it possible to incorporate curves and other imaginative elements into the mezzanine design.

Mezzanines come in various forms, each designed to meet specific needs. Structural mezzanines are integrated into the building’s framework, while freestanding mezzanines stand alone and can be moved or reconfigured. Storage mezzanines maximize vertical space for inventory, and metal mezzanines offer durability and strength. In-plant and plant mezzanines are tailored for use within manufacturing facilities, whereas prefabricated and modular mezzanines are designed for quick assembly and flexibility. Office mezzanines create additional workspace, and warehouse mezzanines are ideal for optimizing storage and logistics. Perimeter mezzanines, on the other hand, extend along the edges of a space, providing valuable additional floor area.

Structural mezzanines are typically integrated into a building during its construction, either receiving partial or complete support from the structure itself. Designed with the intention of maximizing available space, these mezzanines are perfect for accommodating machinery and storing excess products and equipment. By doing so, they help optimize the building’s functionality and efficiency.

Freestanding mezzanines, often crafted from structural steel, exist independently without direct support from the main building. Unlike structural mezzanines, which are integral to the original design and handle more rigorous tasks, freestanding mezzanines are typically added later. They have become increasingly popular due to their flexibility and ease of reconfiguration. These mezzanines are not part of the main structure but rather stand as modular fixtures that can be assembled or disassembled based on evolving needs. They are particularly suited for accommodating heavy machinery, facilitating businesses that need to reposition or relocate their mezzanines, and optimizing floor space.

Storage mezzanines play a crucial role in factories and warehouses by adding valuable extra space for equipment or goods. These mezzanines can be either integrated into the building’s structure or set up as freestanding units. Typically crafted from steel or stainless steel, they offer a durable solution for maximizing storage capacity.

Metal mezzanines are elevated platforms that find their place in a variety of settings, from stores and factories to warehouses and office spaces. These versatile structures are commonly used in industrial and commercial environments to create additional levels for storage or operational efficiency.

In-plant mezzanines are structures built within a plant or facility. Typically, these mezzanines are delivered to their destination in an unassembled state, giving customers the opportunity to assemble them on-site upon arrival.

Plant mezzanines act as intermediate levels within industrial facilities, facilitating smooth transitions between different areas of the plant.

Prefabricated mezzanines are mezzanine systems crafted by manufacturers who design and partially assemble them before delivering them for final assembly by the end-user. Sometimes, these are also known as “pre-engineered mezzanines.”

Modular mezzanines are a form of prefabricated mezzanine, available in standard sizes. They offer a more affordable and faster solution for installation compared to custom options. However, they typically support a lighter load per square foot.

Office mezzanines are elevated platforms that offer a versatile space to enhance and organize office environments, either situated above or below existing areas.

Warehouse mezzanines are elevated platforms that customers install to expand their usable space, either on the ground level or by adding another mezzanine level within their warehouses.

Perimeter mezzanines are incorporated into expansive buildings to offer a vantage point for supervisors to monitor activities on the floor below. These elevated platforms also serve as convenient passageways, facilitating seamless movement across the building.

Shelving and Rack Supported Mezzanines offer a highly efficient storage solution by incorporating additional shelving systems into your current setup. Rather than relying on traditional structural legs, these mezzanines are anchored by rack uprights, making them perfect for optimizing both storage and accessibility. They provide convenient catwalks for easy product retrieval and make the most of your vertical space, seamlessly blending functionality with space-saving design.

Catwalks serve as elevated walkways or aisles that traverse the entirety of a building’s interior. They provide a crucial passage for workers to access and organize products on shelves, racks, or pallets. Sometimes referred to as viewing platforms or maintenance platforms, catwalks are perfect for enhancing floor space, embracing open-air designs, cutting costs on additional storage, reducing moving expenses, and alleviating the burden on the floor.

Full mats blend the characteristics of freestanding and catwalk mezzanine storage systems into a single versatile solution. These systems can be installed over an active workspace or an existing shelving setup, showcasing an open second level. Perfect for managing extensive storage needs and expanding your storage capabilities, they provide an efficient way to handle large quantities of products while creating additional room.

Equipment Components of Mezzanines

The heart of any mezzanine system is its floor, which, along with the structure’s columns, beams, fasteners, and joists, creates a robust and functional platform.

Mezzanine floors, often referred to as “decking,” are typically constructed from a range of materials such as diamond-treaded steel, plywood, metal planks, welded bar grates, and various textured polymer panels. These floors are usually equipped with base plates that facilitate safe movement and stability.

Columns play a crucial role in supporting the diverse loads a mezzanine encounters, whether vertical, horizontal, or twisting. Choosing the right size column is essential for maintaining the safety and stability of your mezzanine. Typically, columns are made from standard tube sizes of 5 inches by 3/16 inches. These dimensions are designed to effectively manage and distribute the weight carried by the primary beams.

Beams play a crucial role in reinforcing and stabilizing the cross-section of the mezzanines. The primary beams serve as the main structural support, ensuring the integrity and strength of the entire system.

Fasteners play a crucial role in ensuring smooth operations below by reducing obstructions. For instance, bolts are integral to mezzanines, serving as a key component in their structure. Depending on the specific needs of the application, manufacturers might stipulate whether the floors need to be bolted together for stability, ensuring they remain securely positioned above the building’s operational and storage spaces. Additionally, anchor bolts are essential for providing the necessary seismic connections to safeguard mezzanines against seismic activity.

Joists serve as the anchors for the decking, bridging across the main beams.

Mezzanine Installation Advantages

Investing in mezzanines offers numerous advantages for businesses aiming to expand. To achieve growth, focusing on efficiency is crucial, and space efficiency plays a significant role in this. Mezzanines enhance space management by maximizing vertical space, making them essential tools for optimizing your workspace.

Moreover, mezzanines offer a cost-effective alternative to extensive building expansions and renovations. By avoiding the expenses associated with taxes, construction materials, labor, and permits, they provide a practical solution for expanding your usable space without altering the overall footprint of your facility.

Additional Advantages of Mezzanine Installation

The otherwise neglected vertical spaces are fully utilized, all without extending the building’s original footprint.

A mezzanine allows the owner to create a clear division between different areas while maximizing the potential of the building’s vertical space.

Swift installation without the hassle of obtaining a building permit, resulting in minimal expenses.

These spaces are ideal for storing heavier equipment or merchandise. They can also be tailored to fit any area, adapting to the specific needs of the facility.

Given that it was set up as a supplementary addition to the building, it can be relocated, moved, or even sold if the mezzanine is no longer needed.

It’s nearly three times cheaper than expanding the ground floor.

Mezzanine Installation Disadvantages

Before beginning the installation, several crucial factors must be evaluated. First, it’s essential to analyze the ground floor layout to choose the most suitable type of mezzanine. You can opt for one supported by posts, which might clutter busy areas and occupy valuable ground floor space, or you can go for a beam-supported mezzanine, which effectively creates an additional level without intruding on the existing floor space.

Mezzanine Design and Customization

Materials

Manufacturers design mezzanines with a keen emphasis on safety and efficiency, opting predominantly for structural steel or stainless-steel plates in their construction. The choice of steel alloys stems from their renowned durability and strength, ensuring the mezzanine can handle substantial loads with reliability.

In industrial environments, however, the choice of materials can vary. When the mezzanine isn’t required to bear heavy loads, manufacturers often turn to fiberglass or aluminum for the flooring components. These materials are lighter and more cost-effective compared to steel, and fiberglass, in particular, excels in resisting corrosion, making it a practical choice for certain applications.

Typically, manufacturers opt for wooden or composite lumber flooring for non-industrial mezzanines. For lightweight or non-industrial mezzanine decks, particle board is often chosen, especially for dry environments. Particle board, a type of wood composite, is made by bonding together multiple layers of wood fibers.

Safety Design

Regardless of their particular design, all mezzanines incorporate features to ensure worker safety. Typically, access stairs are marked with bright colors or reflective tape and designed with treaded surfaces to minimize the risk of slips and falls.

The perimeter railings and handrails enhance safety, while their modular design offers flexibility. Workers can easily adjust them—expanding, reducing, relocating, or disassembling—based on evolving needs or any challenges that arise.

Custom Mezzanines

For specialized needs, mezzanine manufacturers are eager to create custom mezzanines tailored to precise specifications, whether that involves unique shapes or specific floor perforation sizes. They also provide custom footings, crafted from metal or concrete, which serve as a robust foundation for the load-bearing columns of the mezzanine. Additionally, these manufacturers can design mezzanines with custom purlins—structural elements that horizontally support both the flooring and the loads by connecting to the primary frames of the mezzanine.

To enhance the efficiency of storing and retrieving multi-level materials, manufacturers can integrate specialized furnishings that allow workers to safely access and navigate various mezzanine levels. This could include conveyor systems, lifts, stairs, pallet racks, mezzanine racks, shelving units, and roof decking.

Mezzanine manufacturers can seamlessly integrate utilities such as water pipes and electrical conduits into mezzanine floors by routing them through web bar joists. This integration is particularly straightforward and prevalent in steel and structural mezzanines.

Mezzanine Safety and Compliance Standards

To start, it’s crucial that any mezzanines you buy adhere to OSHA (Occupational Safety and Health Administration) standards. Compliance with these standards is essential not only during the purchase but also throughout their use. This commitment helps ensure that your employees remain safe and minimizes the risk of injuries while working on or around the mezzanines.

We also suggest opting for mezzanine products that are certified to meet the standards set by the American Institute of Steel Construction (AISC) and the International Building Code (IBC).

Beyond these, the safety and compliance standards for your mezzanines depend on their specific application and the location of your facility. For instance, if you need a mezzanine that is accessible, it must comply with the ADA (Americans with Disabilities Act). To ensure you meet all necessary requirements, consult with industry experts before finalizing any purchases.

How to Choose the Right Mezzanine Manufacturer

To secure a mezzanine structure, it’s essential to partner with a reputable mezzanine supplier. To make your search easier, we’ve compiled a list of trusted mezzanine manufacturers and suppliers. You can find this helpful list by scrolling up to the middle of the page.

To find the ideal manufacturer for your needs, look for one that aligns with your budget while also delivering outstanding customer service, required certifications, and the options you need. Before exploring potential mezzanine manufacturers, create a detailed list of your specifications, including deadlines, budget constraints, delivery preferences, and post-delivery needs like installation support and parts replacement. This list will sharpen your focus and help you weed out unsuitable options. Review the manufacturers featured on this page, selecting three or four that seem promising. Reach out to each to discuss your project, asking plenty of questions and referring to your list for guidance. After gathering information from each company, compare your interactions to determine the best fit for your needs.

55 Gallon Drums

55 Gallon Drums Floor Gratings

Floor Gratings Mezzanines

Mezzanines Modular Buildings

Modular Buildings Plastic Containers

Plastic Containers Plastic Pallets

Plastic Pallets Plastic Tanks

Plastic Tanks Steel Shelving

Steel Shelving Stainless Steel Tanks

Stainless Steel Tanks Storage Racks

Storage Racks Work Benches

Work Benches Castings & Forgings

Castings & Forgings Bulk Material Handling

Bulk Material Handling Electrical & Electronic Components

Electrical & Electronic Components Flow Instrumentation

Flow Instrumentation Hardware

Hardware Material Handling Equipment

Material Handling Equipment Metal Cutting Services

Metal Cutting Services Metal Forming Services

Metal Forming Services Metal Suppliers

Metal Suppliers Motion Control Products

Motion Control Products Plant & Facility Equipment

Plant & Facility Equipment Plant & Facility Supplies

Plant & Facility Supplies Plastic Molding Processes

Plastic Molding Processes Pumps & Valves

Pumps & Valves Recycling Equipment

Recycling Equipment Rubber Products & Services

Rubber Products & Services